How an Organic Vapor Respirator Cartridge Works

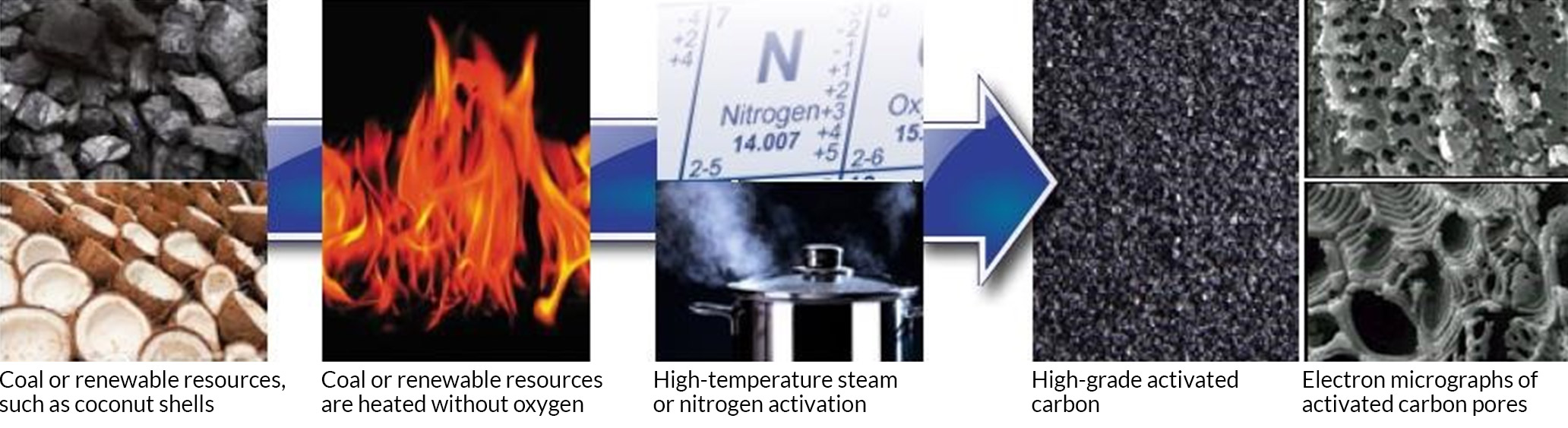

Organic vapor respirator cartridges to help reduce user exposure to many different organic vapours. To achieve this objective, respirator cartridges are filled with a material called activated carbon. Activated carbon is typically made from coal or renewable resources like wood or coconut shells. It is “activated” by heating the material in nitrogen or steam at approximate temperatures of 800 – 900 °C. The resulting material has a significant number of micropores that help adsorb various organic vapours. These micropores can be measured and optimized for specific product needs and performance.

Organic vapor respirator cartridges to help reduce user exposure to many different organic vapours. To achieve this objective, respirator cartridges are filled with a material called activated carbon. Activated carbon is typically made from coal or renewable resources like wood or coconut shells. It is “activated” by heating the material in nitrogen or steam at approximate temperatures of 800 – 900 °C. The resulting material has a significant number of micropores that help adsorb various organic vapours. These micropores can be measured and optimized for specific product needs and performance.

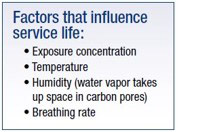

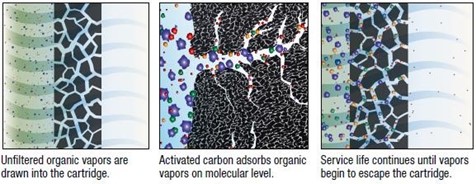

When organic vapours are drawn through an organic vapor cartridge, the air is filtered as vapours condense into the carbon pores. Vapours move through the cartridge from one pore to the next. This occurs more quickly for small volatile vapours with lower boiling points (e.g., acetone). Some migration of organic vapours can even occur during storage, so care must be taken before reusing the cartridge. The effective service life is the time until vapours begin to exit the cartridge. Unlike particle filters, service life is not indicated by change in breathing resistance. Instead, cartridges must be changed according to local regulations; endof-service-life indicator; taste, smell, or irritation from the contaminant; or according to 3M™ Service Life Software calculation, whichever comes first.

When organic vapours are drawn through an organic vapor cartridge, the air is filtered as vapours condense into the carbon pores. Vapours move through the cartridge from one pore to the next. This occurs more quickly for small volatile vapours with lower boiling points (e.g., acetone). Some migration of organic vapours can even occur during storage, so care must be taken before reusing the cartridge. The effective service life is the time until vapours begin to exit the cartridge. Unlike particle filters, service life is not indicated by change in breathing resistance. Instead, cartridges must be changed according to local regulations; endof-service-life indicator; taste, smell, or irritation from the contaminant; or according to 3M™ Service Life Software calculation, whichever comes first.

Activated carbon by itself cannot adsorb other types of gases or vapours such as acid gases, ammonia, formaldehyde, etc. In some cases, additional metals and salts are added to the carbon to selectively remove these compounds. For this reason, 3M offers a variety of cartridges and facepieces to help protect workers in different environments and satisfy personal preferences.

WARNING: These respirators help protect against certain airborne contaminants. Before use, the wearer must read and understand the User Instructions provided as a part of the product packaging. A written respiratory protection program must be implemented meeting all the requirements of OSHACT including training, fit testing and medical evaluation. Misuse may result in sickness or death. For proper use, see packaging instructions.

WARNING: These respirators help protect against certain airborne contaminants. Before use, the wearer must read and understand the User Instructions provided as a part of the product packaging. A written respiratory protection program must be implemented meeting all the requirements of OSHACT including training, fit testing and medical evaluation. Misuse may result in sickness or death. For proper use, see packaging instructions.

064 517 4920

rocky@chlorinetechservices.co.za

www.chlorinetechservices.co.za